The lighting solution uses LED strips from the manufacturer Nenonica.

Here I am using LED strips from European production. Each LED strip has a related documentation, in contrast to cheapest competitor products from the Far East which cost only a fraction. The kitchen uses three different types of LED Stripes:

• 3538 – 300, CRI> 90, 4.8W / m, 300 lm / m – base lighting and for showcases

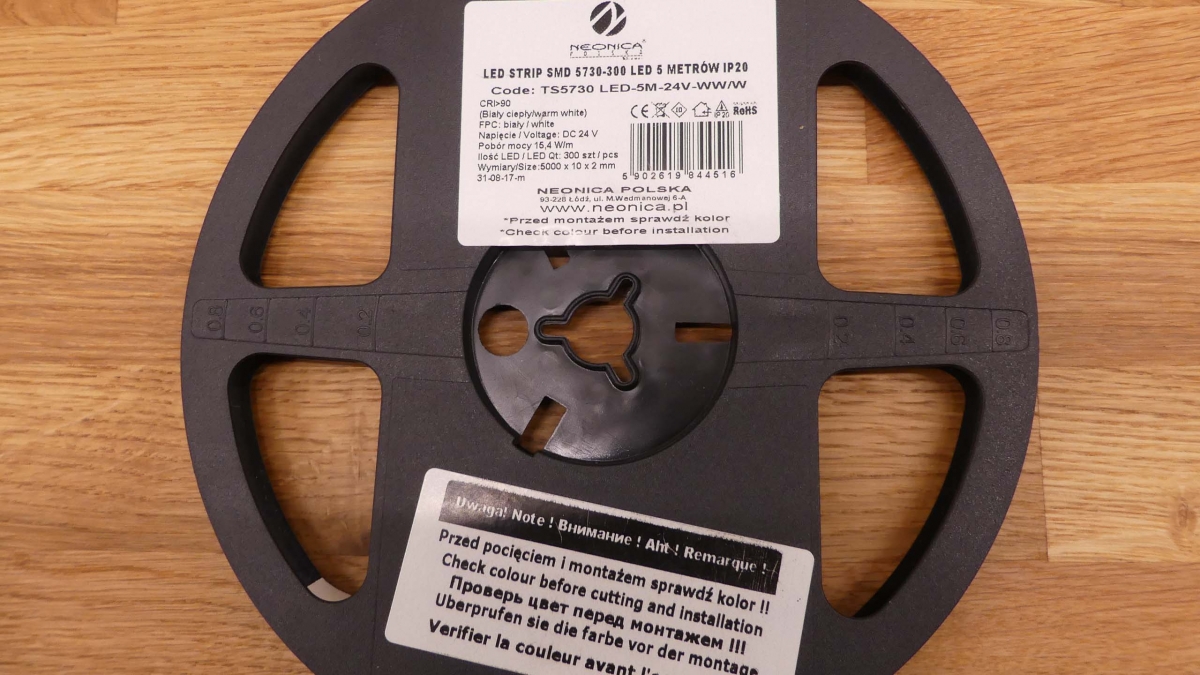

• 5730 – 300 CRI> 90, 15.4W / m, 1690 lm / m – Illumination of all worktops (installed below wallboard, chimney hood and wall cabinets)

• 5630 – 300, Samsung LEDs, 15.6W / m, 2350 lm / m – Main room lighting on the ceiling

The LED Stripes are installed in aluminum profiles specially designed for this purpose. The anodised aluminum profiles not only meet the highest aesthetic standards (even if they are almost never seen due to the indirect light installation), they have a practical use: on the one hand they protect the stripes from mechanical influences and on the other they serve as passive cooling element. They are available in many variants and there are, depending on the type of every conceivable accessory such as covers, profile connectors, wire suspensions etc. My two favorites are the profiles of type SK and type S. Type S is a very inexpensive profile and comes about for the base lighting for use. Type SK is available with high-quality covers, and the cover can be easily clipped in. It is narrow and very aesthetic. On the ceiling a profile of the type GIZA is used. This profile is slightly wider and theoretically can also accommodate two LED strips side by side. Due to the slightly larger width, it diffuses the light as a ceiling profile better than a narrow profile. Since a remnant piece of the ceiling installation was available, this profile is also used in the display case cabinet.

Depending on the type and mounting situation, the profiles are either screwed by means of small countersunk screws (then holes drilled into the profiles and countersink the holes – my favorite mounting option), glued or clipped by means of fastening clips (then the profiles have a distance to the ground, this type of mounting is not very aesthetic, but practical in the case of the base profiles or placed where you can´t see the mounting).

First of all, I can say that the LED installation is much brighter than I ever thought. The LED Stripes completely replace conventional lighting solutions. The lighting situation in the kitchen is completely dimable. In particular, the ceiling lighting is almost never in use because it produces a very bright light brand “lightsaber”. But this was more or less clear, the lighting serves more as “lighting for cleaning” to find every crumb. Preferably the indirect lighting solutions are always in use and they are also more than sufficiently bright.

Anyone who wants to know exactly how much light a light source produces takes a lux meter and measures the illuminance depending on the distance to the light source. DIN EN 12464-1 recommends, for example, for activities in the food and beverage industry an illuminance of 300 lux for cutting fruit and vegetables and a illuminance of 500 lux for the production of delicatessen food and general kitchen work. The values refer to a height of 0.85 m from the ground, ie about worktop height. Has your kitchen fitter ever measured it?

The lighting of the wallboard alone brings it in the middle of the worktop to 541 lux, at the edge of the worktop, it is 216 lux, since the narrow board here even shaded the light.

At the transition between the lighting of the wallboard and the lighting of the chimney hood 600 lux are measured when the LED strips are set to the highest output. If the four 1-watt LED spots of the fan modules are still switched on this is 647 lux (on the surface of the hob the switched lights are visible as reflections).

In the middle of the hob results in a light intensity of 668 lux, right next to it is 613 lux.

The work surface to the left of the sink brings it to 767 lux. This is due to the fact that the wall cabinets, at where at the bottom the LED profile is installed, have a distance of 58cm to the worktop. The chimney hood and the wallboard have 82cm distance.

Light is therefore sufficiently available 🙂 By means of the dimming function the illuminance can be easily adapted to the respective situation.

The overall picture of the lighting: